http://assets.publishing.service.gov.uk/media/542301d040f0b61346000bb7/Falcon_3_195_Hang_Glider_No_Reg_05-12.pdf

2012/05

Falcon (3) 195 Hang Glider - 2010

2011/10/28 12:49 UTC

Darley Moor Airfield, Derbyshire

(Lois Preston) Age - 16 years

13 dual aerotow launches

Pegasus Quantum 15-912

Information Source: Air Accidents Investigation Branch Field Investigation

Synopsis

The student hang glider pilot was carrying out her first solo aerotow launches, having previously completed a number of tandem training flights. Shortly after lift off, the hang glider rolled to the left and, although an initial weight shift correction was made, continued deviating to the left of the tow direction. The towing pilot and the student hang glider pilot both released from the tow line and the hang glider entered a steep nose down, descending spiral into the ground. The student hang glider pilot received fatal injuries.

No defects were found, with either the tug aircraft or the hang glider, that could have contributed to the accident. However, a number of factors were identified that could have made it more difficult for the student pilot to control the hang glider.

The British Hang Gliding & Paragliding Association (BHPA) has initiated an in-depth review of aerotowing procedures and is also reviewing its audit and inspection processes.

History of the flight

Background

The student hang glider pilot had carried out a number of tandem flights and was now considered to be ready for her first solo flight. The tandem flights had been carried out using a Falcon (3) Tandem hang glider. For the solo flight a Falcon (3) 195 hang glider was used. This was considered by the training school to give as similar a set up and 'feel' to the tandem hang glider as possible.

The aerotow launch system used a Pegasus Quantum 15-912 as the towing aircraft. The hang glider was attached to the tow line by means of a two-point bridle and there were separate quick-release systems for the towing pilot and the hang glider pilot.

The weather conditions were good, with a surface wind directly down the runway at around 5 kt. Runway 20 was in use.

First flight

The solo hang glider was set up and the student pilot prepared for the launch. The intention was to tow the hang glider to a height of 1,500 ft aal, before release. A briefing was given which included information about the significant differences between a tandem and a solo flight. When all was ready, the signal was given for the tow to start. The instructor was in a position under the wing, assisting with the launch. He was equipped with a handheld radio transmitter with which he could transmit instructions to the student pilot, if needed, and there was a radio receiver for the student pilot on the hang glider. The towing aircraft was fitted with a rear-view mirror in which the towing pilot could watch the progress of the tow.

The tow commenced, the hang glider lifted off and the student pilot controlled the pitch. The hang glider started to oscillate a little from side to side and then banked left and deviated to the left of the towing aircraft. The student pilot released from the tow and recovered into a level attitude, turned into wind and made a safe landing.

The student pilot and the instructor discussed why the flight had not been able to continue successfully and what corrections to make next time. The student pilot noted the comments and advised that the same mistake would not recur. She was also asked if she wanted to carry out a further tandem flight but decided to attempt another solo flight.

Accident flight

The student pilot was re-briefed before the tow commenced. The hang glider lifted off and started deviating to the left, taking up a left banked attitude. The instructor on the ground, now positioned behind the hang glider, made a radio call to tell the student pilot to "shift right" but, as he did so, saw that a weight shift correction had already been made. However, he noted that the correction was not sufficient to level the wing of the hang glider and that the left turn continued and increased. He radioed to the student pilot to release. The towing pilot and then the student pilot released the tow line; the hang glider then went into a steep nose down, descending left spiral and struck the ground. The instructor later commented that he had been startled by the speed with which the accident had happened and his impression was that the situation was not recoverable.

The area of impact was on a disused concrete/asphalt runway surface. Several people ran over to give assistance and an air ambulance was called. The student pilot was transferred to hospital but had suffered fatal injuries in the accident.

Other information

Witnesses

Using the rear-view mirror, the pilot of the towing aircraft saw the hang glider deviate to the left after it lifted off. She considered that, at the point the hang glider was released from the tow, the situation should have been recoverable. It appeared to her that the student pilot did not make any further control inputs once the hang glider had released.

One witness was watching the aerotow launch from the other end of the runway, some 400 m to 500 m away. He had with him a handheld radio and could hear the transmissions made by the instructor. He saw the hang glider turn to the left, after takeoff, and heard the instructor say to weight shift right. He did not see any sign of a correction but noted that the hang glider turned further left and that the nose up pitch attitude increased. As this happened, he heard the instructor call "release". He could tell that the tow had been released because the pitch attitude of the hang glider changed again. He saw the hang glider continue to turn left and adopt a nose down pitch attitude. The left turn then continued until the hang glider struck the ground.

Meteorological information

The weather conditions were fine and reported by the training school to have been good for aerotowing operations. The wind was not recorded at Darley Moor Airfield but the 1350 hrs METAR for East Midlands Airport, 17 nm to the south-east, reported a surface wind from 210° at 7 kt.

Examination of the accident site

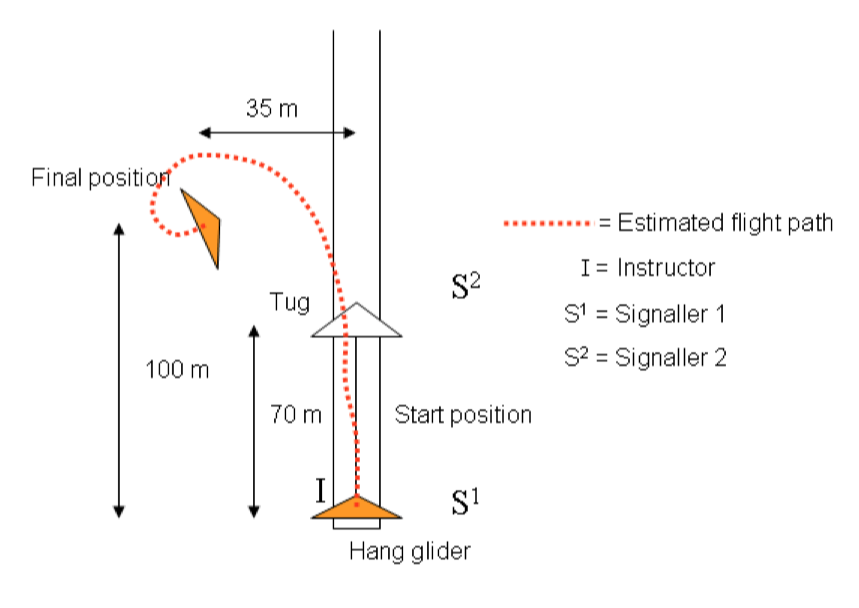

The hang glider was lying on a disused section of a concrete/asphalt runway, located approximately 35 m to the side of the runway from which it had taken off and approximately 100 m from the launch point (see Figure 1). The tow rope was found a little further along the runway in use and was lying at an angle of approximately 30° to the direction of the runway. The hang glider was complete and intact, apart from the control frame which had suffered impact damage. The leading edge on the left side of the wing appeared to have struck the ground first, as the sail cloth along its length was torn. Some dismantling of bracing wires had taken place as part of the efforts to rescue the pilot.

Pilot information

The student pilot had been flying paragliders for two years and had attained a Club Pilot rating. In April 2011 she started hang glider training. The training was carried out in accordance with the BHPA Hang Gliding Aerotow Training Programme and started with tandem aerotows, of which she completed 13. The training programme included recovery from unusual attitudes, stalling and lockout, as well as exercises in recovery techniques for issues that may occur on-tow, such as pilot-induced oscillation and regaining the correct towed position after lateral and vertical displacements. All these exercises were to be carried out at a safe altitude. During training, because of the need to maintain the correct body position, student pilots are first taught to control pitch and roll separately. Later, these are combined into a co-ordinated manoeuvre.

The towing pilot was also a hang gliding instructor and was experienced in aerotow operations, both in flying the towing aircraft and in being aerotowed in solo and tandem hang gliders.

The towing pilot had flown several tandem flights with the student pilot earlier in the day. During them, the student had demonstrated her ability to correct oscillations competently following four simulated oscillation exercises. The towing pilot, in her capacity as an instructor, had considered the student to be very capable and ready for solo flight. Although on the first solo flight the tow was released at a height of about 50 ft, it was competently handled and a safe landing was made, further demonstrating the student's readiness to fly solo.

Towing aircraft

General description

The Pegasus Quantum 15-912 (see Figure 2) is an advanced weight-shift controlled aircraft, operating on a Permit to Fly. It had been modified to include factory modification PG134, which installs a towing hook mechanism, automatic and manual release mechanisms and a rear-view mirror. The procedures and limitations for towing operations using this equipment are set out in the Glider Tug manual, which is a supplement to the Operator's manual. The aircraft had also been modified to include an optional rear hang point for the wing. This provided a slower range of trim speeds, 37 to 55 mph, and is intended for use in this type of towing operation. The wing was rigged to this rear hang point. Towing operations were conducted at a speed of 40 to 41 mph, although, due to the characteristics of the towing aircraft, the speed would reach a higher speed at lift off.

Documentation

The Glider Tug manual includes detailed limitations, instructions and guidance for all aspects of towing with this aircraft. For aerotowing hang gliders, it stipulates that:Among the specified limitations, the following were relevant:'Aerotowing must be carried out according to the BHPA aerotowing operations manual.'Maintenance'The towline must be at least 70 m long....

A maximum weak link strength of 100 kg must be observed according to the BHPA aerotow manual....

Hang gliders to be towed must be capable of a sustainable maximum speed of at least 55 mph.'

The aircraft, G-WHEE, was found to be in satisfactory condition and the towing equipment operated normally. The Certificate of Validity of the Permit to Fly was in date and the aircraft had the required placards displayed. No defects were identified that could affect the towing operation.

The towline being used was 68.3 m long and of the correct material. It had weak links fitted to each end. The weak link at the towing aircraft end had a break value of 150 kgf and the one at the hang glider end had a break value of 125 kgf.

Hang glider

General Description

The Falcon (3) 195 is a conventional hang glider constructed of aluminium alloy tubing frame, with a polyester sail cloth covering. Although not subject to any regulation, the hang glider had been tested and found to comply with an industry-developed design code, the 2006 HGMA (Hang Glider Manufacturers Association) standard. It was considered suitable for novice pilots. The basic weight of the hang glider is 53 lb.

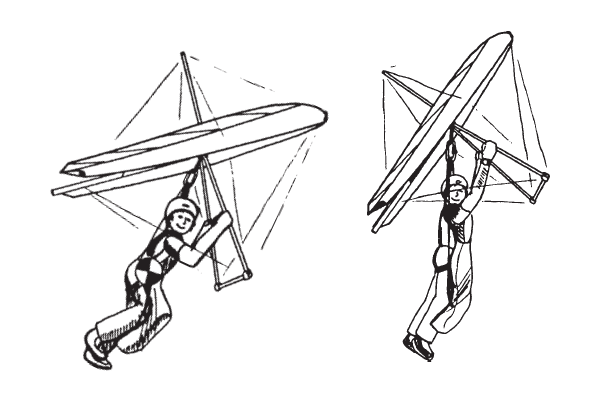

Additional wheels had been fitted to allow ground launching with the pilot in a prone position. A castoring main wheel was attached to each end of the control bar and incorporated rubber bungees to allow a degree of suspension. An extension to the keel allowed the fitment of a tailwheel. (A similar arrangement is showing in Figure 3.) The additional landing gear weighed approximately 28.5 lb.

The hang glider manufacturer was asked to assess the effect on its handling characteristics. Their experience indicated that the control response would generally be slower and the control authority somewhat diminished, due to the percentage reduction in pilot weight compared to the overall weight of the hang glider and the increase in rotational inertia away from the centre of gravity. The manufacturer concluded that it is likely these changes would be noticeable to an experienced pilot but would not compromise a pilot's ability to control the hang glider.

A towing bridle was attached to a point on the keel forward of the control frame and incorporated a quick release fitting which was operated by a lever, similar to a bicycle brake lever, on the right hand side of the control bar. The other end of the towing bridle was attached to the pilot's chest with another independent quick release fitting which could be operated by the pilot. The end of the towline was fitted with a ring, through which the towing bridle passed (see Figure 3). Operating either release allowed the towing bridle to pass through the ring on the towline, releasing the tow.

Documentation

The manufacturer provides an Owner/Service manual which contains detailed limitations, instructions and guidance for rigging and operating the Falcon range of hang gliders. The January 2007, second edition notes:The manual also quoted a recommended 'hook in' pilot weight range of 175 to 275 lb for the Falcon (3) 195 model, based on the compliance testing, but suggested the optimum range is 200 to 240 lb. It notes:'They have not been designed to be motorised, tethered or towed. They can be towed successfully using proper towing procedures. Pilots wishing to tow should be USHGA (United States Hang Glider Association) skill rated for towing.'The student pilot involved in this accident weighed 134.5 lb. It was estimated that her 'hook in' weight was not more than 150 lb.'Be advised that pilots with hook in weights within 20 lbs of the minimum recommended will find the Falcon somewhat more demanding of pilot skill to fly.'

In the flying section of the manual it notes:The manual advises that the normal operating speed range is 20 mph to 30 mph and the maximum steady speed in free flight a pilot can achieve is approximately 42 mph. The VNE is stated as 48 mph. The trim speed can be set by ground adjustment of the hang point position on the keel; the trim speed would typically be set to be within the normal operating speed range.'At speeds faster than trim, you will be holding the bar in pitch against substantial force, and if you let go to move your hand the glider will pitch up and roll towards your remaining hand.'

The BHPA Technical Manual, Section 2, Chapter 7, subpart 4C details the requirements for a hang glider being aerotowed and includes the following requirement for its speed range:The placard on this type of hang glider states that the stall speed at maximum pilot weight is 25 mph and that VNE is 48 mph, giving a mid-range speed of 36.5 mph.'The mid-point of the glider's placarded max All Up Weight (AUW) speed range must lie within the tug's placarded tow speed range. (This is to ensure that the glider is capable of flying at the tug's safe operating speeds).'

Maintenance

There are no formal airworthiness requirements for hang gliders but this one was reportedly inspected regularly, including daily and pre-flight inspections, in line with the requirements of the manufacturer's maintenance schedule. When not in use, it was stored in a hangar in the rigged condition. No maintenance records were available, nor were they required to be kept. The hang glider was reported as being less than a year old and appeared to be in satisfactory condition. No pre-existing defects were found that could affect its airworthiness.

Controlling a hang glider

Control of a hang glider is achieved by the pilot moving their weight relative to the hang glider wing. The shift of weight provides an out of balance force to which the hang glider responds. The weight of the pilot affects controllability, as control is achieved through the movement of the pilot's weight; lower pilot weight results in less control force.

Pitch control

Pitch control is achieved by the pilot shifting their weight forward and aft. Each hang glider has a natural trim or 'hands-off' speed and this is the speed it will fly at without pilot input. The hang glider is stable around this speed and will naturally react to any deviation from this speed and return to its trim speed. For example, if its speed is increased, the hang glider will naturally pitch up and this will cause its speed to reduce. The pilot can fly the glider faster than the trim speed by shifting and maintaining their weight forward. This counters the natural tendency of the hang glider to pitch up as speed increases and, as a result, it will stabilise at a higher speed for as long as the pilot holds their weight forward.

As towing speeds are generally above trim speed, it is common practice to attach one end of the towing bridle to a position on the keel forward of the control bar. This applies a nose down force to the hang glider to assist the pilot in maintaining the correct pitch attitude during the tow.

Roll control

Roll control is achieved by the pilot shifting their weight laterally, from side to side. The roll will commence as soon as the pilot moves sideways due to the, now, uneven weight distribution generating an uneven load across the wing. The wing is designed to flex and help the roll develop. Sideslip towards the lower wing will also develop, as a secondary effect of roll, and this will cause the wing to roll further into the turn and the nose to drop. Due to the natural characteristics of this type of wing, as speed increases it becomes more directionally unstable. The design is, by necessity, a compromise between sufficient low speed control authority and satisfactory high speed directional stability.

Personal safety equipment

The pilot was wearing a helmet approved to European Standard EN966 - Helmets for Airborne Sports. It appeared that it had been subject to considerable force during the accident but had otherwise been in good condition.

Pathological information

An aviation pathologist carried out a post-mortem examination on the pilot. He observed that there was a severe head injury but, apart from fractures of the jaw and a rib, there was no other significant injury. He considered that the force with which the pilot's head struck the ground would have exceeded the helmet's design limits.

Organisational information

The sport of hang gliding is not regulated in the UK but is conducted under the supervision of the BHPA. The BHPA oversees pilot and instructor training standards, provides technical support such as airworthiness standards, runs coaching courses for pilots and supports a country-wide network of recreational clubs and registered schools. The BHPA provides a Technical Manual covering all activities under their supervision.

Aerotowing with a microlight aircraft is a regulated activity and was first approved in the UK by the Civil Aviation Authority in 1994.

The sport of hang gliding has developed around the world during the last 50 years. Hang gliders were initially foot launched from a hill. This method has some limitations; notably that a hilly area is required, the equipment has to be carried to the top of the hill and the weather and wind conditions have to be suitable. This means that the learning process is often lengthy and is usually carried out as a solo pilot, although some tandem flights are available.

Launch systems were developed, using winches or static lines, and some of these are suitable for tandem hang gliders. Aerotowing is a more recent activity, which allows a tandem hang glider, with an instructor and student, to be towed to a greater height, typically around 3,000 ft aal, thereby allowing more airborne and training time. Training can take place over a generally flat area, giving smoother air conditions and a possible landing back at the launch point. Thus, more training flights are possible in a shorter space of time.

Aerotowing is widely considered to be the most demanding of the hang gliding launch procedures. Some pilots progress through foot launching and winch launching before attempting aerotows. Ab initio aerotow training is carried out at a number of locations. The BHPA advises that a typical number of tandem launches before solo flight is between 15 and 20. Recognising the demanding nature of aerotowing, this school introduced an assessment system, such that students were evaluated on their ability during the early tandem flights. Only the more able were allowed to progress towards an aerotowed first solo; other students progressed using a winch launch system.

Aerotow operation on the accident flight

The hang glider was fitted with integral wheels for the launch; this was a similar configuration to the tandem hang glider used for training. More commonly, for a solo launch, a trolley is used which remains on the ground after the hang glider lifts off. The BHPA considered a trolley launch to be a progression and that early solo flights should be kept as similar in configuration to the tandem flights as possible.

A number of people were involved with this aerotow launch procedure. As well as the towing pilot and the student pilot, there was the instructor, with a radio, who was on the ground, alongside the student pilot at the start of the launch. There was an observer (Signaller) by the hang glider, equipped with a bat to signal when all was ready for the tow to start, and an observer (Signaller 2) ahead of the towing aircraft to receive and relay these signals to the towing pilot (see Figure 1).

Several instructors, who were familiar with aerotow operations, noted that it was fairly common for students to enter an oscillation after takeoff during the early stages of their training.

Analysis

Training

The student pilot had completed a structured training programme at a BHPA approved school. Although the number of dual aerotows completed was less than the typical number reported by the BHPA, the instructor considered that the student had demonstrated that she was more than capable of progressing to solo flight and additional dual training was not necessary.

The training programme was comprehensive and included recovery from unusual attitudes, stalls, lockout and oscillations. However, such training is, by necessity, carried out at a safe altitude with an instructor.

During the first solo flight, initially a lateral oscillation developed, followed by a deviation to the left. The student pilot released herself from the tow and made a controlled landing into wind. The recovery manoeuvre was carried out well and gave the instructor additional assurance that the student pilot was ready for solo flight.

The second solo flight started with a roll and deviation to the left at an early stage. Although there was an attempted correction, it was not sufficient and the deviation increased. This time, the towing pilot released first. The student pilot released soon afterwards but the hang glider would have been exposed to different release forces from those experienced during the first solo flight. It is possible that the student pilot delayed making corrections as a result of her experience during the first solo flight.

Although the training is designed to expose a student to many possible scenarios, when an unusual attitude or event is experienced close to the ground the pilot's view is different because of the changed perspective. Furthermore, the time available to make a recovery is short and requires quick, accurate corrective action.

Towing aircraft and hang glider

No defects were found with either the towing aircraft or the hang glider that could have contributed to the accident.

The pilot's hook-in weight was below the minimum recommended for the hang glider. Although the additional landing gear increased the overall weight, it did not form part of the moveable weight used to control the hang glider. The low pilot weight would have, according to the manufacturer's literature, made the hang gliderThe speed range of the towing aircraft should match the speed range of the hang glider, to enable both to remain within their design limitations during the tow. The towing aircraft has a tow speed range of 37 to 55 mph. Towing operations were conducted at a speed of 40 to 41 mph, although, due to the characteristics of the towing aircraft, the speed would be higher at lift off. Whilst this was within the recommended hang glider speed range, the operating limitations for the towing aircraft required the towed hang glider to have a sustainable maximum speed of 55 mph. This hang glider has a VNE of 48 mph and in free flight the maximum sustainable speed a pilot can achieve is around 42 mph. Also, the BHPA Technical Manual requires the mid-point of the hang glider's speed range to be within the placarded tow speed range of the towing aircraft. In this case, it was just below that.'somewhat more demanding of pilot skill to fly'.

General takeoff characteristics for this aircraft combination

During the launch, the speed of the hang glider increases to near its recommended maximum in the period from just after lift off until the towing aircraft has taken off. The speed then reduces to the normal tow speed in the climb out. This means that the hang glider is above its trim speed and, therefore, requires a nose down input to prevent it from climbing out of position. This force is provided, in part, by the pilot but mainly by the end of the towing bridle attached to the keel.

The directional stability of the hang glider becomes increasingly unstable as its speed increases. In the period just after lift off, a student pilot is taught to control pitch to avoid climbing too high and, separately, to control any roll deviation that may develop. At this time, the towing aircraft's speed peaks and the hang glider is close to its maximum recommended speed and is, therefore, more directionally unstable. Instructors commented that inexperienced pilots often develop lateral oscillations just after takeoff, which is an indication of this inherent instability. More experienced pilots have the skill to correct and manage this instability before it develops into an oscillation. If a lateral deviation develops, the speed of the hang glider will increase further (much like a water skier traversing behind a boat) and this increase in speed makes it more unstable and, therefore, more difficult to control.

Accident flight

The student pilot appears to have controlled pitch and maintained the correct vertical position during the takeoff but, from shortly after lift off, the hang glider did not maintain the correct lateral position behind the towing aircraft. The length of the tow line being used was just below the minimum length specified by the Tug Manual and that recommended by the BHPA Technical Manual. This reduced the pilot's margin for error and meant any angular deviations would develop more quickly. A longer tow line effectively allows more time for a pilot to recognise and react to any deviations.

The hang glider rolled to the left soon after lift off. Once it started to deviate from the proper towing position, its speed and, therefore, the nose up pitch force would have increased rapidly. The towing bridle attached to the keel would have helped the pilot to counter this force, up to the limit of the tow line weak link. Although the weak link fitted to the tow line was above the value specified by the Tug Manual and recommended by the BHPA Technical Manual, it was not possible to determine whether or not a weak link of the specified value would have broken and released the tow before the tow line was manually released by the towing pilot.

As the deviation to the left developed, it would have rapidly reached a point where the pilot no longer had sufficient roll control authority and the only course of action was to release the tow. The towing pilot saw the deviation developing and released the tow line. This was closely followed by the student pilot releasing the tow line, using the hand lever on the control bar. At the point of release, the tow line tension was likely to have been high and the release would have caused the hang glider to pitch up rapidly as a natural response to the removal of the nose down force on the keel.

Because the hang glider was banked to the left, the pitch up would have been into the turn. The action of the pilot in moving her right hand to release the tow could have caused the glider to pitch up and roll left even more. By this stage, the situation may not have been recoverable, especially for a student pilot with the limited height available.

Safety actions

The BHPA has initiated an in-depth review of aerotowing procedures and will be paying particular attention to the equipment being used and any special requirements for initial solo flights.

The BHPA is also reviewing its audit and inspection processes for aerotowing operations, to ensure that all the elements identified in the above review are regularly and thoroughly checked.

Further relevant actions

Following this accident, the manufacturer of the towing aircraft reviewed the Glider Tug manual and has applied to the BMAA to remove the hang glider sustainable maximum speed requirement. This is to ensure there is no conflict between operating criteria in this manual and that contained in the BHPA Technical Manual, Section 2, Chapter 7 which covers aerotowing procedures for hang gliders. A statement requiring all aerotow operations to be in accordance with the BHPA aerotowing procedures will remain.

Conclusions

From shortly after takeoff, the hang glider did not maintain the correct position behind the towing aircraft and entered an increasing roll to the left. It rapidly deviated from the desired flight path and, despite the tow line being released, resulted in a loss of control from which the student pilot did not recover.

A number of factors were identified that could have made it more difficult for the student pilot to maintain the correct towed position.

The BHPA has initiated an in-depth review of aerotowing procedures and is also reviewing its audit and inspection processes.

---

Footnotes:

1. The signal for the tow to start was passed from the hang glider pilot to the towing pilot via the instructor and two Signallers (see Figure 1).

2. Lockout - This is when a hang glider turns away from the direction of the force applied by the tow line, to such an extent that the tension in the tow line causes the hang glider to deviate rapidly, at an increasing rate, and the pilot no longer has sufficient control authority to correct it. Once developed, the only way to recover is to release the tow line.

---

Figures:

1 - Diagram of the accident site

2 - Towing aircraft, G-WHEE (courtesy Derbyshire Constabulary)

3 - Similar hang glider showing pilot position and bridle arrangement

TOW - Towing bridle - Keel