Hang Gliding & Paragliding Vol42/Iss06 Jun 2012 by US Hang Gliding & Paragliding Association - issuu

HIGHER EDUCATION - 2012/06

TIE A (BETTER) WEAK LINK

by Drs. Lisa Colletti and Tracy Tillman

A WEAK LINK WALKED INTO A BAR...

TRACY: You're a surgeon; do you need to know much about knots and strings?

LISA: I seriously have to know about knots and strings. It's not very cool to have a knot come undone inside somebody when they are recovering from surgery.

TRACY: Yeah, that's serious and technical stuff. Most of this article is going to be serious and technical. So, let's start on the not-so-serious side. How about telling your knot and string story?

LISA: Nearly 20 years ago, you had a consulting job to do in southern California, and I tagged along to do some flying. After a day of fun for me and work for you, I met up with you and some of your colleagues at a very upscale restaurant in San Diego. You guys were all dressed nice, and I showed up in dirty, torn, grass-stained jeans and a t-shirt, with messed-up "helmet head" hair. I'd had a way-fun day of flying.

The hostess at the restaurant was NOT happy about my looks and attire, and said so, but she went ahead and sat us all in a corner of the restaurant, away from the other patrons. We proceeded to have a great time, with lots of drink and talk, and a joke came up. It was the string joke. It goes something like this...

We were sitting at the table, when a string walked over and said, "This is a nice place. Do you suppose they serve strings here?" We told the string that we didn't know; he should go up to the bar to find out.

So the string went up to the bar and asked for a beer. The bartender said, "Hey, you look like a string. Sorry, we don't serve strings here." The string came back to our table, looking bummed and told us the bartender wouldn't serve him. We told him to go to the other end of the bar; maybe that bartender would serve him.

So the string went to the other end of the bar and asked for a glass of wine instead of a beer, hoping to fit into the ambience of the place a bit better. The bartender said, "I saw you asking for a drink at the other end of the bar. You look like a string--sorry, we don't serve strings here."

The string came back to our table, looking really pissed-off rather than bummed. We told the string to relax, sit down and try one more time when the waitress came back to our table. When the waitress came over, the string told her she'd get a big tip if she would get him a bottle of their best champagne. The waitress said, "I'd like to serve you. It's $300 a bottle, and it would be great to get a nice tip--but, we don't serve strings here. Aren't you a string?"

The string just lost it. He rubbed his hair frantically, folded his arms and said, "I'm a frayed knot!" (Afraid not.)

TRACY: Yeah, that's a good one! But this article is about weak links used for aerotowing. What's the connection to frayed knots?

LISA: Many pilots don't really understand weak links. Simply, the ideal weak link used for aerotowing consists of a continuous loop of string or length of material, without a knot in it--especially not a frayed knot--because a knot weakens the string and weakens it inconsistently, resulting in inconsistent breaking strengths.

TRACY: The idea of using a continuous loop of string is great, but knot--I mean not--practical. It is too hard to make and attach a continuous loop of string.

LISA: Ah, but there's a way to get close to that ideal. Before we get into the specifics of how to tie a better weak link, let's discuss some of the legal and practical aspects of weak links.

TRACY: OK. Now, we are going to get serious and technical, with numbers and calculations. If readers want to know details on the WHAT and WHY of weak links, they should continue reading from here. If they just want to know the HOW they can skip most of the words and numbers and jump down to the section with the pictures.

LISA: Oh, like reading a Playboy magazine.

TRACY: I'll start with a legal review. The FAA has mandated requirements for weak links in FAR 91.309(a)(3) [ref 1] for civil aircraft towing sailplanes, ultralight gliders, and hang gliders in the US. It states:and(3) The towline used has a breaking strength not less than 80 percent of the maximum certificated operating weight of the glider or unpowered ultralight vehicle and not more than twice this operating weight. However, the towline used may have a breaking strength more than twice the maximum certificated operating weight of the glider or unpowered ultralight vehicle if--

(i) A safety link is installed at the point of attachment of the towline to the glider or unpowered ultralight vehicle with a breaking strength not less than 80 percent of the maximum certificated operating weight of the glider or unpowered ultralight vehicle and not greater than twice this operating weight.So, for the weak link at the hang glider end of the towline, the FAA mandates a breaking strength that is 80% to 200% of the maximum certificated operating weight (MCOW) of the glider. The MCOW of the glider is the total allowable weight of the glider, pilot, harness, and anything else attached to the glider, based on certification. In contrast, USHPA aerotow guidelines recommend a weak link breaking strength of 1G, which is 100% of the actual operating weight of the hang glider [ref 2]. A weak link that breaks at the actual operating weight of the glider may or may not fall within FAA requirements, depending on where the weak link is placed.(ii) A safety link is installed at the point of attachment of the towline to the towing aircraft with a breaking strength greater, but not more than 25 percent greater, than that of the safety link of the towed glider or unpowered ultralight vehicle end of the towline and not greater than twice the maximum certificated operating weight of the glider or unpowered ultralight vehicle.

LISA: Could you explain how that works, with examples?

TRACY: I'll explain how that works by comparing FAA weak link requirements with USHPA recommendations for (a) a very light, small hang glider, (b) a larger heavier hang glider, and (c) a tandem glider.

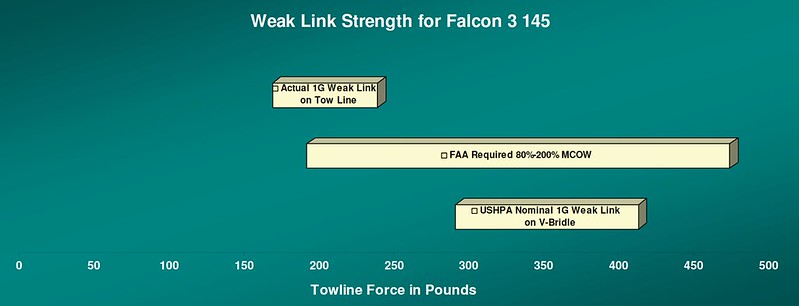

If you look at the specifications for the Falcon 3 145 on the Wills Wing web site [ref 3], it shows that the hook-in weight range is 120 to 190 lbs. The glider weighs 45 lbs. and the maximum hook-in weight allowed is 190 lbs., so we can assume that the total MCOW for this glider is 235 lbs. That means--per the FAA's requirements--the weak link on the hang glider end of the towline must have a breaking strength between 188 lbs. and 470 lbs., which are 80 percent and 200 percent of the operating weight of the glider, respectively. If a pilot hooks in at the high limit of 190 lbs., then per USHPA's recommendation of using a 1G weak link, the weak link should have a breaking strength of the actual 235 lb. operating weight of the glider, which is within the FAA required range of 188 to 470 lbs. If a pilot hooks in at the low limit of 120 lbs., then per USHPA's recommendation of using a 1G weak link, the weak link should have a breaking strength of the actual 165 lb. operating weight of the glider, which would be below the FAA required range of 188 to 470 lbs.! Any pilot with a hook-in weight less than 143 lbs. would have to use a weak link with a breaking strength of more than 1G to be legal. Conversely, a pilot who hooks in at the low limit could legally use a weak link with a breaking strength of up to 470 lbs.

LISA: That would be a 2.85G weak link, which is 285% of a 1G weak link.

TRACY: That example assumes that the weak link is placed directly on, or in line with, the towline, such as on the end of the towline or at the apex of the pilot's V-bridle. The situation is different when the weak link is attached to one end of a V-bridle, such as at the top of the V-bridle, where it connects to the primary release. To break at a certain towing load, the strength required of the weak link on the V-bridle would be half of that load, plus about 15% due to the vector angle of the bridle. It works out to be a ratio of about 0.575 to 1 for a typical 3-point bridle. This ratio is dependent on the length of the V-bridle and the angle it makes relative to the towline, which is explained in the Pagen/Bryden book Towing Aloft [ref 4]. As such, USHPA's 1G recommendation for weak link strength for a weak link on a V-bridle is considered a nominal 1G value, rather than an actual 1G value. Using the same ratio of 0.575 to 1, a nominal 1G weak link on the end of the V-bridle equates to about 1.74G of force on the towline.

If a pilot flying a 45 lb. Falcon 3 145 hooks in at the high limit of 190 lbs. and uses a nominal 1G weak link of 235 lbs. at one end of the V-bridle, the weak link will actually break when the load on the tow rope is 409 lbs., which is within the FAA required range of 188 to 470 lbs. If a pilot hooks in at the low limit of 120 lbs. and uses a nominal 1G weak link of 165 lbs. at one end of the V-bridle, the weak link will break when the actual load on the tow rope is 287 lbs., which is also within the FAA required range of 188 to 470 lbs.

The relationship for an actual 1G weak link placed on or inline with the towline for a Falcon 3 145 compared to the FAA's requirements and a nominal 1G weak link placed on the V-bridle is illustrated in the chart below.

LISA: So when an actual 1G weak link is placed directly in line with the tow rope, it will not be FAA-legal across the pilot hook-in weight range of the glider--but a USHPA-recommended nominal 1G weak link placed on one end of the V-bridle will be legal across the pilot hook-in weight range for the glider and is relatively in the middle of the FAA's required range for breaking strength.

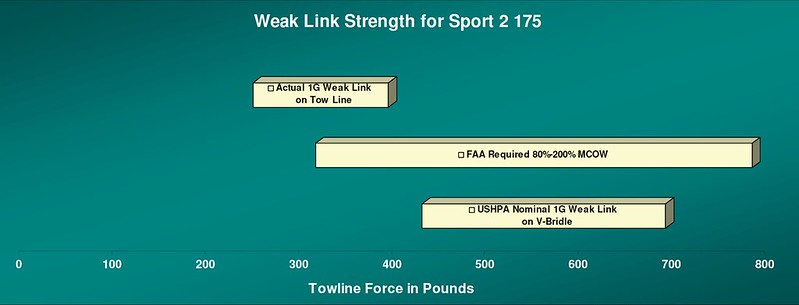

TRACY: Let's look at another example for the larger and heavier Wills Wing Sport 2 175. Their web site [ref 3] shows that the hook-in weight range is 175 to 320 lbs., and the glider weighs 70 lbs. We can assume that the MCOW for this glider is 390 lbs. In this case, per FAA requirements, the weak link used for the hang glider must have a breaking strength between 312 lbs. and 780 lbs. if it is placed directly inline or on the towline. The actual operating weight of the glider can range from 245 to 390 lbs. If an actual 1G weak link was used on or inline with the towline, anything used less than 312 lbs. would not be FAA-legal. Conversely, a pilot who hooks in at the low limit could legally use a weak link with a breaking strength of 780 lbs., which would be a 3.18G weak link.

If a pilot flying a Sport 2 175 hooks in at the low end of the allowable range and places a nominal 1G 245 lb. weak link on one end of his/her V-bridle, the weak link would break when actual towline load reaches 426 lbs. If a pilot hooks in to the Sport 2 175 at the high end of the allowable range and places a nominal 1G 390 lb. weak link on one end of their V-bridle, the weak link would break when actual towline load reaches 678 lbs. The range of 426 to 678 lbs. is within the FAA-legal limits of 312 and 780 lbs. So again, a nominal 1G weak link placed on the V-bridle is legal for all allowable hook-in weights for this glider. This relationship is illustrated in the chart above.

LISA: Again, an actual 1G weak link attached in line with the towline will not always meet FAA requirements, but a USHPA nominal 1G weak link placed on the V-bridle will be FAA-legal and will be relatively in the middle of the FAA required range of breaking strength. You mentioned that you would also give an example for a tandem glider.

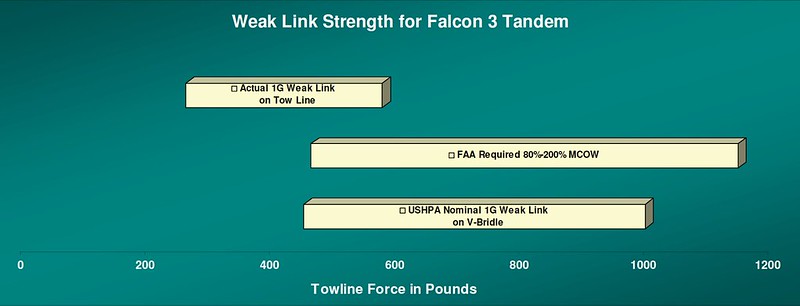

TRACY: According to the specifications for the Falcon 3 Tandem that are posted on the Wills Wing web site [ref 3], the allowable hook-in range is 185 lbs. to 500 lbs., and the glider weighs 71 lbs. MCOW can assumed to be 571 lbs. The FAA would require use of a weak link for the hang glider that breaks when towline loads are anywhere between 457 lbs. and 1142 lbs., which is 80% to 200% of MCOW.

If an actual 1G weak link was used and placed directly in line with the towline, it could have a breaking strength as low as 256 lbs. or as high as 571 lbs., depending on hook-in weight. Any actual 1G weak link used that is below 457 lbs. would not be FAA-legal. However, if a nominal 1G weak link was placed on one end of the tandem's V-bridle, it could handle towing loads as low as 445 lbs. to as high as 993 lbs., depending on hook-in weight.

This relationship is illustrated below.

LISA: So, except for the very lightest pilot scenario, a nominal 1G weak link placed on the V-bridle is legal across the recommended hook-in weight range of the glider, whereas it is not for an actual 1G weak link placed in line with the towline.

TRACY: Actually, if the tandem's V-bridle was made just a little bit longer, to change the force vector angle and reduce the load placed on the weak link, a nominal 1G weak link would work across the entire hook-in weight range for the tandem glider.

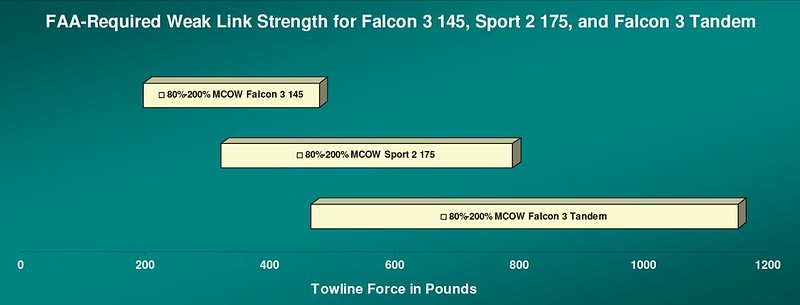

LISA: Can the same strength weak link legally be used for different sized gliders?

TRACY: Sure, as long as it is a weak link that breaks when tow forces reach 80% to 200% of MCOW For the particular glider being towed. For example, we can legally use weak links for the small and light Falcon 3 145, placed on the V-bridle, that can range from 108 to 270 lbs. Comparatively, we can legally use weak links for the larger and heavier Sport 2 175, placed on the V-bridle, that can range from 179 to 449 lbs. The overlap is 179 to 270 lbs., so any weak link within that range could legally be used for both these gliders.

LISA: So, the typical weak link used for aerotowing most hang gliders, made as a single loop from 130 lb. line, will have a nominal 1G breaking strength of 260 lbs. and be legal for both the very small, light glider and the heavier, larger glider--assuming there is no reduction in strength of the weak link due to a knot in the line.

TRACY: And these are extreme cases. When we look at gliders and pilots of more average size, the standard 260 lb. weak link placed on the end of the V-bridle is FAA-legal for most gliders and pilots, and closer to the USHPA nominal 1G recommendation.

LISA: What about the weak link used for a tandem glider?

TRACY: OK, let's look again at the specs for the Falcon 3 Tandem glider on the Wills Wing web site [ref 3]. The glider weighs 71 lbs., and the maximum allowable hook-in weight is 500 lbs. This means the MCOW of the glider is 571 lbs. The FAA would require use of a weak link with a breaking strength of 457 lbs. to 1142 lbs., if it was placed directly in line or on the tow rope. If placed at the end of the tandem pilot's V-bridle, a legal weak link would have a breaking strength between 263 and 675 lbs.

LISA: So the standard 260 lb. weak link used for solo gliders is not quite strong enough to be legal for the Falcon 3 Tandem.

TRACY: Actually, it could be legal if a longer V-bridle was used to reduce the load experienced by the weak link.

LISA: If a stronger weak link was used, could the same weak link legally be used for the small Falcon, the large Sport 2, and the Tandem glider?

TRACY: Legally, yes! Assuming that the force vector angle of the V-bridles was the same for all three gliders, it would require use of a weak link on the V-bridle with a breaking strength between 263 and 470 lbs., which equates to being between 458 and 470 lbs. of towline force.

The overlap is illustrated in this chart:

LISA: There is a fair bit of overlap between the two solo gliders, and a fair bit of overlap between the large solo glider and the tandem glider, and even a little overlap between the small solo glider and the tandem glider. The FAA's requirements for weak link breaking strength are not very restrictive. Your description helps to show that the allowable range is quite wide, and that because of that wide range, the same strength weak link can legally be used to tow most solo and tandem hang gliders. Although legal, that may not be so practical, as we will discuss in detail later.

TRACY: It gets a bit more complicated when it comes to calculating the legal requirements for the weak link at the tug end of the rope. But in the example given above for hang gliders, the tug could legally use the same weak link for all three gliders if it was only slightly stronger than the one used by the hang glider pilots, but not greater than 270 lbs. if placed at the end of the tug's V-bridle or 470 lbs. if placed directly in line with or on the towline. The way to make the weak link just slightly stronger on the tug is to use the same weak link, but with a longer bridle that has a more acute angle so that the resultant load is less and the tow load breaking strength is a little higher.

LISA: Some people may not understand the difference between nominal values and actual values.

TRACY: Nominal is a categorical reference [ref 5]. For example, most everybody knows that 2x4 lumber is not actually 2 inches thick and 4 inches wide. It roughly starts out that size when first cut, but by the time it is finished being made, the actual dimensions are about 1 1/2 inches by 3 1/2 inches. Here's another example of a nominal classification: NiCad batteries are given a nominal value of 1.2 volts, but their actual voltage can range from 1.45 volts to 1.0 volt, depending on state of discharge. [ref 6]

Likewise, the USHPA nominal 1G value for weak links is a handy guideline for pilots, as they can easily figure out the approximate strength of the weak link that they should use on their V-bridle, based on their glider's actual operating weight. There is no specific range of tolerance specified for USHPA's nominal 1G recommendation--it is not meant to be an exact requirement. The actual weak link used by the pilot must, according to the FAA, perform appropriately for the operation [ref 7], and function within FAA legal limits [ref 1].

LISA: You covered some legal aspects of weak link strength. Being legal is important, but so is being practical. Let's talk about some practical aspects of weak links.

TRACY: Unlike the FAA's relatively clear-cut legal rules, the practical aspects of weak link technology and application are not so clear-cut. For some people, talking about weak links is more like talking about religion, politics, or global warming--they can get very emotional about it and have difficulty discussing it logically, rationally, or with civility.

LISA: So let's try to talk about it rationally, logically, and practically here.

TRACY: Let's start with the definition of practical. A good definition of practical [ref 8] is: "of, relating to, governed by, or acquired through practice or action, rather than theory, speculation, or ideals."

LISA: Even though the FAA does not specify the technology of weak link construction, there are practical, accepted standard methods of constructing and attaching weak links for sailplanes and hang gliders.

TRACY: That's because there are two types of standards, de jure and de facto [ref 9].

De jure standards are those dictated by law, like the FAA's requirement for weak link strength or created by a standards organization, like ASTM standards for construction of light sport aircraft. Neither the FAA nor ASTM has a de jure standard for weak link construction. About all that the FAA has to say about it is: "Tow ropes and weak links are assembled using a tow ring that is appropriate for the operation" [ref 7].

Similarly, ASTM standards state: "The rated ultimate strength of the weak links to be used in the towing cable shall be established and shown to be suitable in operation" [ref 10].

De facto standards are those that are market driven and have received wide acceptance by the industry. De facto standards result from many organizations adopting the use of them. When it comes to weak links, the FAA lets the industry and marketplace develop, sell, and use what works--meaning that which is practical and "appropriate to the operation" [ref 7].

LISA: I get it--it's like de jure and de facto standards for hang gliders. Hang gliders must meet FAA de jure standards as unpowered ultralights under FAR part 103, and should meet HGMA de jure certification standards. But, the common design and construction methods used by hang glider manufacturers are de facto standards, as are the selection and use of hang gliders by individuals and organizations.

TRACY: Right. The FAA doesn't require hang glider manufacturers to make hang gliders a certain way. It is a practical de facto standard that hang gliders are made from aluminum tubing, carbon fiber, steel wire, bolts, other hardware, and Dacron, Mylar, and some other sail materials. Likewise, it is a practical de facto standard that light, easy-to-fly single-surface gliders are used for training, and that heavier, more difficult-to-fly topless gliders are usually used by competition pilots.

LISA: Flying an appropriate glider is practical. The FAA doesn't dictate that to us for solo flight, as long as we meet the requirements of FAR part 103 when we fly.

TRACY: Right again. Likewise, the FAA regulations and ASTM standards allow us to use whatever weak link design works for our towing operation, as long as it is appropriate to the operation and falls within their required range of breaking strength. If, after all these years, the FAA--and more recently ASTM--have not set specific design and construction requirements for weak links for sailplanes, they are probably not going to set specific weak link design and construction requirements for hang gliders, either.

LISA: Sailplane weak links rarely fail inadvertently--that's not so much the case for hang gliding weak links. To help people understand why this is so, I think that it would be good to describe and compare de facto standard sailplane weak link designs with hang glider weak link designs.

TRACY: One standard weak link design for sailplanes is to just use the tow rope itself as the weak link, as long as it has a breaking strength between 80% and 200% of the MCOW of the glider, per FAR 91.309(a)(3). The de facto standard is to use 1/4", 5/16", or 3/8" hollow braid polypropylene rope, commonly with breaking strengths of about 1000 lbs., 1500 lbs., and 2000 lbs., respectively [ref 11]. These tensile strengths can vary a bit, depending upon manufacturer of the rope. Any of those three rope diameters would be legal for us to use as a weak link for our Blanik, with a MCOW of 1100 lbs., but, practically, we feel that 1500 lbs. is best. Of the three diameters of polypro tow rope, only 1/4" tow rope would be legal for us to use as a weak link for our Alatus ultralight sailplane.

LISA: 1000 lbs. is at the maximum limit for our Alatus. Practically, it is better for us to add a lighter weak link at the end of the 1/4" tow rope for the Alatus.

TRACY: Adding a second, lighter weak link on to the towline is a very popular de facto standard weak link design for sailplanes. Here, a thicker row rope is used as the weak link for the tug and a short length of thinner row rope is attached to the glider end of the long tow rope as the weak link for the glider. The short length of thinner rope can be spliced directly into the thicker tow rope or attached to the end of the tow rope using hardware. Splices are used rather than knots, because knots significantly and inconsistently reduce the strength of the rope. We prefer this weak link style for our Blanik as well as the Alatus. For the Blanik, we use 3/8" polypro as the towline and 5/16" polypro as the weak link line added to the end of the towline. This way, the weak link for the glider is 1500 lbs. and the weak link for the tug is 2000 lbs., which is 25% greater than the weak link for the glider, but not more than twice the MCOW of the glider.

The top rope in the picture above is a 5/16" polypro 1500 lb. tow rope that defaults as the weak link for both the tug and sailplane, the middle one is a 3/8" polypro 2000 lb. tow rope that defaults as the weak link for the tug with a 5/15" 1500 lb. weak link for the sailplane spliced into the end, and the bottom rope is an alternative 5/16" 1500 lb. weak link that can be separately attached to a tow rope. The top two use a TOST-style tow ring for use with a TOST release mechanism, while the bottom one uses a Schweizer tow ring for use with a Schweizer release mechanism.

LISA: Those approaches to weak link design are very practical and are widely used for sailplanes. It is important to realize that most sailplane operations use polypro for the tow rope rather than Spectra. Unlike Spectra, polypro has some stretch to it under load--and can stretch up to 20% before breaking. It acts like a shock absorber to soften impact loads, which helps to prevent damage to the structure and hardware of the tow plane and sailplane and helps to avoid unnecessary weak link breaks.

TRACY: A third practical, but less common and more expensive, de facto standard for sailplanes is use of a metal TOST weak link. This weak link design is more commonly used in Europe than in the U.S., and is more commonly used for winch towing. The TOST weak link is a small strip of metal precisely fabricated to break at a specific load, within a tolerance of plus/minus 5% [ref 11]. It can be attached to one or both ends of the towline with shackles, and is covered by a protective metal sheath. A primary and secondary TOST weak link can be mounted together under the same protective sheath, so that the secondary is a back-up in case the primary weak link fails prematurely. They will both fail properly in an overload situation. TOST weak links come in eleven different color coded sizes, including sizes light enough to be used for hang gliders.

LISA: How about describing de facto standards for weak links used for aerotowing hang gliders?

TRACY: Based on several decades of experience and hundreds of thousands of tows conducted by numerous aerotow operators across the county, the de facto standard has become use of a 260 lb. weak link made as a loop of 130 lb. green spot IGFA [ref 12] Dacron braided fishing line attached to one end of the pilot's V-bridle. It is a de facto standard, because it works for most pilots and gliders and is usually near the USHPA recommendation of a nominal 1G weak link for most pilots. For example, a mid-size Sport 2 155 with a pilot who has a hook-in weight that is in the middle of the recommended weight range will weigh about 260 lbs., so a loop of 130 lb. line is just right. This strength of line also meets FAA requirements for most sizes of gliders and weights of hang glider pilots. Lighter green spot line is available for very light pilots, and heavier line is also available for heavier pilots, tandems, and the tug.

It is important to realize that, per FAA requirements, the weak link on the tug cannot be more than 25% stronger than the weak link used for the glider. That means, in most cases, for solo pilots when 130 lb. green spot is used to make a 260 lb weak link, the weak link attached on one end of the tug's V-bridle should have a breaking strength that is no more than 325 lbs. Green spot 160 lb. line works great for a weak link on the tug's V-bridle, because it makes a 320 lb. weak link, which is just under the 25% greater limit of 325 lbs. If a trike or some other tug is used where the tug's weak link is incorporated as part of the towline, rather than on a V-bridle, the tug's weak link should have an actual breaking strength of about 520 lbs. if towing a hang glider using a nominal 1G 260 lb. weak link on the V-bridle. This can be adjusted up or down a bit for performance and to stay within FAA requirements, but is convenient because a double loop of 130 lb. green spot line can be used to make a 520 lb. weak link.

The same approach works for tandem gliders, but the numbers are higher. For example, if the total weight of a tandem glider with pilot and student is 416 lbs., then per the USHPA recommendation of using a nominal 1G weak link, the weak link on the tandem glider's V-bridle should be 416 lbs. and no more than 520 lbs. for the V-bridle on the tug. In this case, a loop of 200 lb. green spot line could be used to make a 400 lb. loop for the tandem glider's weak link, and a double loop of 130 lb. green spot could be used to make the 520 lb. weak link for the V-bridle on the tug. Of course, the FAA would legally allow us to use a much stronger weak link, up to 675 lbs. as we described earlier for a Falcon 3 tandem, but it may not be practical to use such a strong weak link on a tug's V-bridle.

Historically, a 520 lb. double loop of 130 lb. green spot line has been the de facto standard for weak link used on the V-bridle for both the tandem and the tug. Technically, this can be legal if the V-bridle on the tug is longer and has a more acute angle than the V-bridle on the glider, which results in a vector angle that effectively makes the weak link on the tug act slightly stronger than the weak link on the glider. There has been a trend lately for some tandem operators to go with about a 400 lb. weak link on both the tandem glider and tug V-bridles, rather than 520 lbs., to help protect the equipment from large stresses. If tandem operators think that, practically, a 520 lb. double loop weak link is too much for a tandem, it is way too much for a solo pilot.

Solo hang glider pilots should not place a 520 lb. double loop weak link on their V-bridle, unless they get specific approval from the tow operator. It could be hard on the equipment and could be illegal if the tug is using a weaker weak link. It is also far beyond USHPA's nominal 1g recommendation.

LISA: Why is green spot IGFA braided Dacron fishing line used?

TRACY: It ties well, it holds up well, and has about the right tensile strength, and, according to John Vitek, who does line testing for IGFA, it breaks very consistently near 130 lbs. A caveat is that his experience is with line supplied to him by manufacturers, distributors, users, and world record applicants. He said that it is possible that the tensile strength of some line made by a manufacturer could vary more than the line samples that he has received and tested. He also said that if an aerotow operator wants to send him a sample of weak link line to be tested, he will be happy to do it for IGFA's usual fee.

IGFA braided Dacron fishing line is readily available in a wide range of strengths that work for us, including 100, 130, 160, 180, 200, 250, and 300 lb. line. One source states that their Dacron braided line is IGFA approved, and they publish a chart of the actual tested breaking strengths for their various lines [ref 13]. They state that their 130 lb. line breaks within one pound of 130, which is 5 to 10 times more precise than a metal TOST weak link. Their least precise 180 lb. line breaks within four pounds of 180 lbs., which is still twice as precise as a metal TOST weak link.

LISA: Can you explain some methods of constructing weak links for hang gliders?

TRACY: Sure. I'll start by discussing some methods that may be legal, but are not common de facto standards. One method would be to make the entire tow rope a weak link, which is a de facto standard for aerotowing sailplanes. For example, a 200-foot length of 400 to 500 lb. braided line would work and be legal as a tow rope that also functions as a weak link for aerotowing most hang gliders. Unfortunately, this line would have such a thin diameter that it would not hold up well to the whipping and dragging on the ground that it would experience over multiple tows. If this were practical, people would be using it as a standard method.

Another method would be to attach a TOST metal weak link to one or both ends of a stronger towline, like they do for sailplanes in Europe. It would work fine at the tug end of the towline, but it may not be practical to have a relatively flat and sharp strip of metal at the end of the towline near the hang glider pilot.

Likewise, it would probably not be practical to put it on the pilot's V-bridle, because it is a flat and sharp piece of metal and would not pass through the tow ring well at release. If this were practical for hang gliding, people would be using it as a standard method.

LISA: How about explaining some accepted standard methods of making weak links for hang gliders?

TRACY: An old de facto standard, from the early days of aerotowing hang gliders, involved placing a pre-tied 1G weak link loop directly on to the end of the tow rope or at the apex of the pilot's V-bridle. This was a method borrowed from surface towing. Early ultralight tugs did not have much power compared to the LSA tugs used today, and weak links could be weaker. The climb angles were shallow and the tow forces were lighter, so an actual 1G weak link used in-line with the tow rope was practical--and likely the basis for creation of the original 1G USHGA recommendation for weak link strength. Like today, a 130 lb. line would work fine for making the weak link. Some older literature on hang glider aerotowing describes tying weak links for use on a V-bridle with an extra knot in the line to weaken it. In this situation, the weak link on the V-bridle would only be about l/2g, but would break when about a 1g load was placed on the tow rope. [ref 4]

The LSA tugs used today are much more powerful, with greater climb angles and tow forces. To prevent inadvertent weak link breaks, the de facto standard today is to place a 1g weak link, usually 260 lbs., on the end of the V-bridle instead of on the tow rope or at the apex of the V-bridle. The USHPA recommendation of making a weak link with a 1G breaking strength still applies, but the 1G weak link is now normally placed on one end of the V-bridle instead of onto or in line with the tow rope. The current 1G recommendation is a nominal value, whereas the original 1G recommendation was an actual value. Bear in mind, that a 1G weak link placed in-line with the tow rope may not be FAA-legal, if a light pilot is flying a big glider with a high MCOW, as we explained earlier. However, in almost all cases, a 1G weak link placed at the end of the pilot's V-bridle will be FAA-legal.

LISA: So, specifically, what standard de facto methods are now used for tying weak links for hang gliders?

TRACY: Today, there are two generally accepted and widely used methods for tying weak links: (a) Pre-tied and (b) Wrap and Tie (WT). One involves pre-tying the weak link line into a loop before putting it on the V-bridle; the other involves threading the weak link line through the loop at the end of the V-bridle, wrapping it three to five times, and then tying it to make a loop.

To make a pre-tied weak link, a short 9-10" length of line is tied into a loop with a grapevine knot, then attached to the smaller loop at the end of the V-bridle with a lark's head knot [ref 4]. The resultant loop should be one to two inches long--if longer it can whip and snag on to the tow ring as it passes through the ring at release. Pre-tied weak links made from 130 lb. green spot line work well for many aerotowing operations, are practical and appropriate for those operations, and thus this method has become a de facto standard.

The picture to the left shows the length of line, tied into a loop with the grapevine knot, then attached to both a thin Spectra and a thicker polypro bridle with a lark's head knot. Note how much more surface area is provided by the polypro bridle, so that pressure subjected to the weak link by the bridle is spread out over a much a larger area, and is thus reduced per unit area of the weak link which helps to reduce the chance of an inadvertent weak link break.

Some aerotowing operations--particularly ones with more powerful tugs like ours here at Cloud 9--have found that pre-tied weak links fail inconsistently and too frequently. Sometimes they perform well by breaking as expected under high loads, and not breaking inadvertently in mild turbulence, but sometimes they fail unexpectedly. This inconsistent weakness is likely caused by (a) the knot in the line that is used to pre-tie the weak link, (b) the garroting action of the lark's head knot, and (c) the ability of the weak link to loosen, shift, and wear. This is exacerbated by use of a Spectra bridle rather than a polypro bridle due to the smaller surface area of the Spectra bridle line and the inability of Spectra to absorb shock.

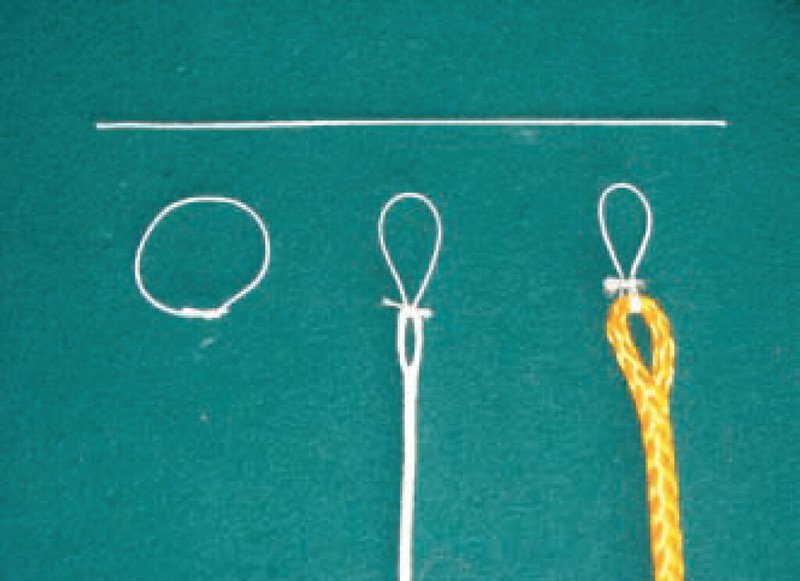

We and some other tow operators get significantly better results by using a Wrap-and-Tie (WT) weak link, made of the same 130 lb. green spot line. To make this kind of weak link, cut a 12-inch piece of line, thread it through the loop at the end of the V-bridle, wrap it around three to five times, and tie it with a simple overhand knot at the very end.

Then, add two more overhand knot ties, just inside the other ones. Pull the inner loop to use as your weak link, leaving the knots on the inside of the V-bridle loop, so that the knots are separated by the remaining loops as much as possible from the pulling force applied on the weak link in the middle. Here at Cloud 9, we prefer wrapping five times, so that the center loop is used for the weak link, and the knot is separated from the weak link loop by the two additional loops on each side of it.

The picture on the following page shows the cut piece of line, threaded through and wrapped five times around the loop of the bridle, and then tied at the end with three overhand knots. The knotted end of the weak link is moved into the inside of the bridle loop, and the middle loop of the weak link is pulled out. Then the middle weak link loop is pulled tight, snugging down the additional outer loops on to the bridle. The resultant loop should be one to two inches long to prevent it from snagging on to the tow ring.

The WT style of weak link performs very consistently, likely due to the extra weak link loops snugging down onto the bridle and not shifting around, and because the knot used to make it is separated far from the pulling pressures. Basically, it removes the knot from the actual weak link loop that is used, so it behaves much like a continuous loop of line without a knot in it.

LISA: What about a three-line weak link?

TRACY: It is an acceptable method [ref 4], but not necessarily a de facto standard. It can be used to make, for example, a 390 lb. weak link from 130 lb. line for use on a tug. It requires the use of two knots, one at each end of the weak link to attach it to the bridle or ring, and it doesn't really work on a pilot V-bridle. A practical option would be to just make a 400 lb. WT loop from 200 lb. line.

LISA: You and I have flown sailplanes for almost as long as we have flown hang gliders. We own two sailplanes and have two airplanes that we use for towing full-size sailplanes. In all the time that we have flown and towed sailplanes, we have not experienced or even seen a sailplane weak link break.

LISA: It's not that it doesn't happen, but it is a rare occurrence. Russell Brown, a founder of Quest Air in Florida and a well-known Dragonfly tug pilot, is also a sailplane pilot, tug pilot, and A&P mechanic for a large commercial sailplane towing operation in Florida. He told us that, like us, he has never seen a sailplane weak link break, either. Russell owned the first 914-powered Dragonfly ever made--he helped us build the second one, which we still fly. He is the one who, many years ago, showed us the method for making a WT weak link and suggested we use polypropylene rather than Spectra for hang glider V-bridles.

Jim Lee, two-time US Hang Gliding National Champion and six-time US comp point champion, was our commercial pilot sailplane instructor. He is a sailplane distributor, instructor, and tow pilot in Florida. He recently told us that he has only seen two sailplane weak link breaks, and experienced one himself, when he and the tow plane had to turn sharply on tow to avoid a helicopter that flew into their flight path. He said that his weak link performed properly in that situation.

TRACY: So, let's look at the purpose of weak links used for sailplanes. The FAA doesn't say much about that in print. Based on other literature and what we have learned, weak links are primarily used to help prevent structural failure of the glider or tow plane when unusually high loads are applied on the towing system. The SSA specifies the purpose of a weak link as: "designed to break under extreme load to prevent damage" [ref 14]. They should be weak enough to fail before anything on the tow plane or gliders fails, but not so weak that unintentional breaks occur. In addition to preventing structural failure, weak links may break: (a) to prevent loss of control of the tow plane or glider in unusual attitudes, (b) when tow forces increase as a glider gets outside of the cone of safety, and (c) sooner or later after a lockout has started.

A pilot should not expect a weak link to break to prevent a lockout. Sometimes the pressures produced at the start of a lockout are high, and the weak link may break early. Sometimes the pressures are not very high at the start of the lockout and don't get high until the lockout progresses much further--in that case the weak link will break later. In either case, the primary purpose of the weak link is to protect the structure and equipment of the glider and tug by separating them--it is not to prevent a lockout.

LISA: Actually, that is our expectation of performance for weak links on hang gliders here at Cloud 9, too. Primarily, we want the weak link to fail as needed to protect the equipment, and not fail inadvertently or inconsistently. We want our weak links to break as early as possible in lockout situations, but be strong and reliable enough to avoid frequent weak link breaks from turbulence. It is the same expectation of performance that we have for the weak links we use for towing sailplanes.

TRACY: Practically, some hang glider aerotow operators may want to use weak links that are at the low end of the legal range, let's say with an actual breaking strength between 80% and 100% of the MCOW of the glider. In this case, they may experience more unintentional breaks, but breaks will occur with less stress applied to the structure of the tow plane or glider. In this case, there is less likelihood that the tug will experience loss of control or structural failure before a weak link breaks when a glider gets out of the cone of safety. On the other hand, some operations may want to use weak links that are stronger but legal, primarily to avoid unintentional weak link breaks.

Either case is legal if within FAA limits, and can be ethical and practical if it works effectively and safely for that operation. The strength of the weak link that is appropriate for a particular operation can depend on the power of the tug and resultant climb rate and climb angle of the tow. To be legal, a hang glider pilot should not just use any strength weak link they want to use, it must be within legal limits, and coordinated with the weak link used at the tug end of the rope.

We have very powerful tugs here at Cloud 9 with very large and efficient Prince P-tip propellers. The diameter of the propellers we use on our Rotax 914 engines is the same diameter as the propellers we have on our Skymaster 225 hp engines--in fact, because of the P-tip, the effective diameter is increased by 6 inches, to 84 inches, which is 7 feet [ref 15]. The climb rate we get is amazing. Weather permitting, we tow on a daily basis here through most of the flying season, but we only see a few weak link breaks here each season. Most of our solo pilots here at Cloud 9 use the 130 lb. line, so that they are towing with a 260 lb. nominal 1G WT weak link on a polypro V-bridle, which equates to using an actual 1.7G weak link on the towline.

Dr. Lionel D. Hewitt, professor of physics and developer of the 2-to-1 center-of-mass Skyting bridle for surface towing, is well respected for his knowledge of towing, bridles, and weak links [ref 4]. His position on weak link strength for aerotowing of hang gliders seems to be consistent with ours. He has acknowledged that we especially need to avoid inadvertent weak link breaks while aerotowing, because much of aerotowing takes place over unlandable terrain. That, along with recognizing that towing pressures vary considerably while on aerotow, has led him to suggest the use of a weak link that breaks in the neighborhood of 1.5G of towline pressure [ref 16]. This is near to what actually results when a USHPA-recommended nominal 1G weak link is placed at the top end of a V-bridle used for aerotowing.

LISA: We know that some aerotow hang gliding operations and pilots experience a relatively high incidence of weak link breaks. Why do you think that happens?

TRACY: There are many reasons, but for most pilots it is not because the standard 130 lb. green spot Dacron line used to make weak links for hang gliders is too weak.

One problem for them could be use of a pre-tied weak link, which has both a grapevine knot and garroting lark's head knot that can cause the weak link to break inconsistently. Sailplane weak links avoid using knots, and the WT style of weak link effectively doesn't have a knot near the working weak link, which allows the line to maintain its integrity and break reliably as needed.

Another factor is the size and material used for the pilot's V-bridle. A Spectra bridle has almost no stretch, so sharp, impact loads are transferred directly to the weak link, while a polypro bridle has a reasonable amount off stretch and can act as a shock absorber and reduce the intensity of the impact load.

LISA: Without shock absorption, a Spectra bridle acts somewhat like an impact wrench on the weak link.

TRACY: Right. It just hammers away at it. A Spectra bridle typically has a relatively small diameter and thus applies a type of garroting action on the weak link, compared to a larger diameter polypro bridle, which spreads the pressures over a larger area of the weak link. Also, the shorter the V-bridle, the more stress is applied to the weak link due to the resultant vector of force. The worst performance comes from a relatively short Spectra or thin pro-tow bridle, especially when the weak link is attached directly onto the thin curved pin of the secondary release, which imparts high loads over a very small area of the weak link. The best performance comes from three-point bridle using an appropriately long primary V-bridle made from 1/4" or 5/16" diameter polypro. The overall length of a three-point bridle system is much longer than that of a short pro-tow bridle, and thus will have more stretch and shock absorbing quality. Here at Cloud 9, we experience the most reliable weak link performance by using WT style weak links and three-point polypro primary and secondary bridles.

The use of a Spectra bridle is an accepted de facto standard, and works well for many towing operations. It just does not work well for our towing operation here at Cloud 9.

LISA: We used to see more weak link breaks happen here at Cloud 9 in the past, when more visiting pilots flying here were using pre-tied weak links and Spectra bridles. Because Spectra is slippery, we also used to see their bridles sometimes slip apart on tow. Some bridle makers are sewing their Spectra bridles now. We just have not had a problem with our polypro bridles slipping apart.

TRACY: There are other factors that affect weak link performance. Faster tows create more drag, which increases load on the weak link, and makes the turbulence impart a sharper impact load on the weak link. Higher climb rates and climb angles impart more load on the weak link, as does towing in a position that is too high or low, or too far to the side, rather than in the center of the cone of safety. Towing without a fin decreases directional stability and smoothness of the tow, which increases load and wear on the weak link. Likewise, pro-towing decreases smoothness and the ability to control the tow and can increase loads on the weak link, as described earlier.

These factors lead to a relatively high frequency of weak link breaks at aerotow hang gliding competitions. An inadvertent weak link break places a pilot at a competitive disadvantage and can increase the chance of personal injury or damage to their glider--which is also a competitive disadvantage.

To be safer and tow more smoothly, a comp pilot could use a small fin [ref 17] on his/her glider and use a three-point V-bridle instead of a pro-tow V-bridle. If they want to stick with a pro-tow bridle, they could reduce the likelihood of an inadvertent weak link break by: (a) using a polypro rather than Spectra bridle, to reduce the intensity of the shock load placed on the weak link; (b) making their bridle a bit longer so that the force vector on the weak link has the effect of making the weak link stronger; (c) using a slightly stronger weak link, such as 160 lb. rather than 130 lb. line--but only if that stronger weak link is coordinated with the weak link used by the tug; and/or (d) using a WT-style weak link rather than a pre-tied weak link, so that it will more consistently break at its intended strength.

LISA: Finally, everyone should know that thorough aerotow training and currency results in a more proficient aerotow pilot who can tow more smoothly and can stay more precisely in the center of the cone of safety [ref 18]. When hang glider pilots can fly their gliders on tow as smoothly as a sailplane flies on tow, it is less likely that they will experience an inadvertent weak link break. Is that it for this article?

TRACY: We could get into details of lab testing weak links and bridles, but this article is already getting long. That would be a good topic for an article in the future. Besides, with our backgrounds in formal research, you and I both know that lab tests may produce results with good internal validity, but are often weak in regard to external validity--meaning lab conditions cannot completely include all the factors and variability that exists in the big, real world.

What we have covered in this article is practical information and knowledge gleaned from the real world of aerotowing, developed over decades and hundreds of thousands of tows by experts in the field. This information has practical external validity. Hopefully, someone will develop methods and technology that work better than what we are using as standard practice today. Like the methods and technology used today, it is unlikely that the new technology will be dictated onto us as a de jure standard. Rather, to become a de facto standard, that new technology will need to be made available in the marketplace, proven in the real world, and then embraced by our sport.

LISA: I m looking forward to that. You were right; this has been a serious and technical discussion. So to finish, I have another joke...

An old weak link walks into a bar and sits down next to a string. The string says, 'This is a string bar, they don't serve weak links here. Aren't you a weak link?" To which the weak link replied: "No, I'm a frayed knot!"

TRACY: You know, you've got to be kind of weird to tell a joke about weak links.

LISA: And just as weird to understand it!

This article was peer-reviewed and approved for publication by the USHPA Towing Committee.

Lisa is the Associate Dean and Professor of Surgery at the University of Michigan Medical School, and is past chair of the USHPA Towing committee. Tracy is a retired university professor, current chair of the Towing committee, and regional director for USHPA Regions 7 & 13. He is also a FAAST Team Safety Counselor for the FAA Detroit FSDO area. They are both very active multi-engine commercial airplane and glider pilots, tug pilots, and tandem hang gliding instructors for the Dragon Fly Soaring Club at Cloud 9 Field (46MI), Michigan. Please feel free to contact them about towing related issues at cloud9sa@aol.com.

---

Illustrations:

Page 16

photo:

Tracy

Page 18

photo:

Nominal 1G Weak Link here ->

=1.74 G here

Page 18

graphic:

Weak Link Strength for Falcon 3 145

Actual 1G Weak Link on Tow Line

FAA Required 80%-200% MCOW

USHPA Nominal 1G Weak Link on V-Bridle

Towline Force in Pounds

Page 19

graphic:

Weak Link Strength for Sport 2 175

Actual 1G Weak Link on Tow Line

FAA Required 80%-200% MCOW

USHPA Nominal 1G Weak Link on V-Bridle

Towline Force in Pounds

Page 20

graphic:

Weak Link Strength for Falcon 3 Tandem

Actual 1G Weak Link on Tow Line

FAA Required 80%-200% MCOW

USHPA Nominal 1G Weak Link on V-Bridle

Towline Force in Pounds

Page 21

graphic:

FAA-Required Weak Link Strength for Falcon 3 145, Sport 2 175, and Falcon 3 Tandem

80%-200% MCOW Falcon 3 145

80%-200% MCOW Sport 2 175

80%-200% MCOW Falcon 3 Tandem

Towline Force in Pounds

Page 23

photo:

polypro sailplane weak links and tow rings

Page 24

photo:

130 pound Greenspot loops Lark's Headed onto Spectra and Polypro

Page 26

photo:

130 pound Greenspot Wrapped and Tied onto polypro

---

References

01. "Towing: Gliders and UnPowered Ultralight Vehicles." Title 14 CFR Part 91.309:

http://ecfr.gpoaccess.gov/cgi/t/text/text-idx?c=ecfr&sid=095a2e79c9ef532c2a007af7076bf5dc&rgn=div8&view=text&node=14:2.0.1.3.10.4.7.5&idno=14

02. USHPA written Aerotow (AT) examination.

03. Wills Wing web site:

http://willswing.com

04. "Towing Aloft." By Dennis Pagen and Bill Bryden, 1998. Sport Aviation Publications.

05. http://en.wikipedia.org./wiki/Dimensional_lumber#Dimensional_lumber

06. http://en.wikipedia.org./wiki/Real_versus_nominal_value

07. FAA "Glider Flying Handbook." (FAA-H-8083-13) p.6-3:

http://www.faa.gov/library/manuals/aircraft/glider_handbook/media/faa-h-8083-13.pdf

08. http://www.thefreedictionary.com/practical

09. http://aiimstandardswatch.typepad.com/aiim_standards_watch/2007/05/defacto_vs_deju.html

10. ASTM Standard F2245-11 Annex 1 "Additional Requirements for Light Sport Airplanes Used to Tow Gliders" A1.6.1.6.:

http://www.astm.org/Standards/F2245.htm

11. TOST weak link information:

http://www.wingsandwheels.com/page30.htm

12. International Game Fish Association website:

http://www.igfa.org/

13. Tuf Line Break Strength Chart:

http://www.fishingtackledepot.biz/TUF.LINE-PREMIUM-DACRON-BRAID-s/2079.htm

14. "Soaring Tech: Unique Soaring Terms." By Bill Collum. Definition of a Weak Link. Soaring magazine, October 2009, p.11.:

http://www.ssa.org/magazine/archive/ViewIssue.aspx?year=2009&month=10

15."Towline: Dragonfly Tales: Tails, Tips, Tricks and Treats." by Lisa Colletti and Tracy Tillman, Hang Gliding and Paragliding magazine, September 2007:

http://www.ushpa.aero/article.asp?id=54

16. Dr. Lionel D. Hewett, Interim Chair Department of Physics, Texas A&M University-Kingsville. Various comments posted online.

17. "Higher Education: Welcome to Fin Land." by Lisa Colletti and Tracy Tillman, Hang Gliding and Paragliding magazine, March 2012:

http://issuu.com/us_hang_gliding_paragliding/docs/1203_final?mode=window

18. "Higher Education: More about Aerotowing and the Cone of Safety." by Lisa Colletti and Tracy Tillman, Hang Gliding and Paragliding magazine, September 2011:

http://issuu.com/us_hang_gliding_paragliding/docs/1109_web?mode=window